» Technical Docs.

DESIGN NOTES – BEARING LIFE :

Wear and service life of the DUROFIT slide bearings are dependent on the following:

* Specific bearing load

* Sliding speed

* PV value

* Roughness depth of the mating surface

* Mating surface material

* Temperature etc. and so on

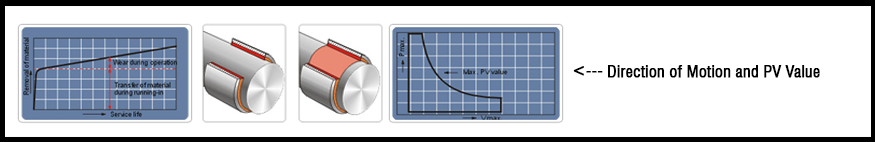

During running-in, some of the surface of the PTFE/Pb or solid lubricants is transferred to the mating surface. A running surface is formed which has low coefficient of friction and this has a positive effect on the operating behaviors. For 3-layer dry bearings, after running-in, some of the porous bronze layer can be seen on the sliding layer as individual areas of different size. This shows that the bearing is functioning correctly. The PV value has a considerable influence on the bearing service life. It is the product of the specific load P and the sliding speed V and the PV is very important design data, we recommend design lower PV value will leads to a longer service life.

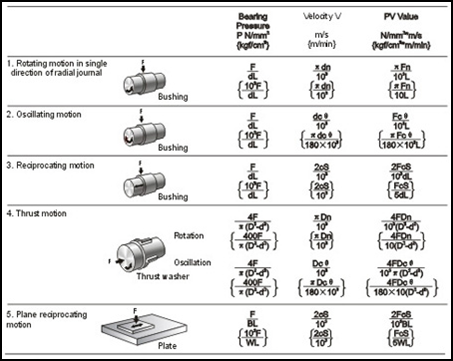

| F: Vertical load...........................N{ kgf } | N: Number of rotation...............S-1{ rpm } |

| C: Cyclic velocity of reciprocating or oscillating motion | S: Stroke distance...................................m{ mm } |

| θ: Oscillating angle.................................rad{ } | d: Bearing ID.........................................mm{ mm } |

| D: Bearing OD............................................................mm{ mm) | L: Bearing length...................................mm{ mm } |

| W: Bearing width.......................................................mm{ mm } | |

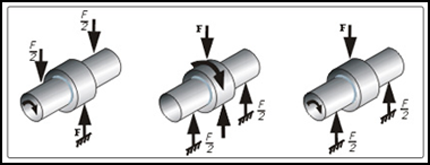

• Influences on the service life: In general, the bearing pressure is obtained by dividing the max load imposed on the bearing by the pressure supporting area of the bearing. The pressure supporting area is defined as the projected loading area which contacts with the shaft, projected in the direction of the load in cases of a cylindrical and spherical bearings.

• Influences on the service life: In general, the bearing pressure is obtained by dividing the max load imposed on the bearing by the pressure supporting area of the bearing. The pressure supporting area is defined as the projected loading area which contacts with the shaft, projected in the direction of the load in cases of a cylindrical and spherical bearings.

• Operation intervals : Operation may either be continuous or intermittent. Intermittent operations can be advantageous for general type bearings because of intervals which allow generated friction heat to cool down. This enables a PV value to remain relatively high. The disadvantage of intermittent operations is that frequent operational interruptions tend to cause inadequate amount. Moreover, resulting in increasing wear occur when restarting. The heavy load imposed in an intermittent operation is liable to cause boundary lubrication condition. A bearing should be selected which safely endures friction and wear in that condition. Oil-containing bearings self-supply lubricant oil to the sliding surface, and exhibit excellent lubricant-maintaining capability. DUROFIT solid lubricant embedded bushings in particular has a high load carrying capacity and displays excellent performance in intermittent operations with high load because of the tough film of solid lubricants covers the sliding surface.

• Operation intervals : Operation may either be continuous or intermittent. Intermittent operations can be advantageous for general type bearings because of intervals which allow generated friction heat to cool down. This enables a PV value to remain relatively high. The disadvantage of intermittent operations is that frequent operational interruptions tend to cause inadequate amount. Moreover, resulting in increasing wear occur when restarting. The heavy load imposed in an intermittent operation is liable to cause boundary lubrication condition. A bearing should be selected which safely endures friction and wear in that condition. Oil-containing bearings self-supply lubricant oil to the sliding surface, and exhibit excellent lubricant-maintaining capability. DUROFIT solid lubricant embedded bushings in particular has a high load carrying capacity and displays excellent performance in intermittent operations with high load because of the tough film of solid lubricants covers the sliding surface.

• Oscillating Motion: The oscillating motion is considered to be one of the most severe conditions to bearings zero velocity in each cycle of motion. Oil film is liable to be disrupted, fatigue and wear of material be accelerated and wear particles tend to remain longer.

The ball bearing which are designed mainly for rotational motion have a very small contact area causing, extreme high contact stress to develop at their pressure supporting areas. They are, thus, unsuitable for oscillating motion because which have large contact sleeve bearings which have large contact area are generally considered better for this application.

DUROFIT self-lubricating bearings are the most adequate bearings for oscillating motion having a very tough sliding surface which generates little wear particles, and being an oil-containing type which will not cause noise due to disruption of oil film.

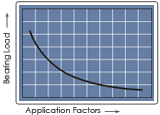

• Velocity: The main cause of generated heat is the work done at the friction surface of the bearing. It is known from experience that the rise in temperature at the friction surface is affected more by the velocity than by the pressure. With the same PV value, the larger V value is, the high bearing temperature will be.

• Velocity: The main cause of generated heat is the work done at the friction surface of the bearing. It is known from experience that the rise in temperature at the friction surface is affected more by the velocity than by the pressure. With the same PV value, the larger V value is, the high bearing temperature will be.

When used in a high velocity operation, it is recommended that the bearings should be designed and used in such a manner that the co-efficient of friction be reduced by positive supply of oil to enhance both cooling and lubricating effectiveness, in order to take advantage of their wear resistance.

• Bearing Temperature : The life of a bearing is greatly influenced by environment temperature and friction heat that is generated from oscillating and reciprocating motion. For a high temperature application, the PV value of the bearing should be limited to a small value.

• Bearing Temperature : The life of a bearing is greatly influenced by environment temperature and friction heat that is generated from oscillating and reciprocating motion. For a high temperature application, the PV value of the bearing should be limited to a small value.

The heat resistance of plastic bearings is generally inferior to that of metallic bearings. In particular thermoplastic resins poor resistance to heat. They also have high thermal expansion rate. Consequently to maintain a min. Required clearance, careful dimensional control is necessary when the bearings of these materials are designed.